Nippon Glass Industry Co., Ltd. Corporate Customers

toukon soil

It is suitable for construction on steep slopes as well as the kneading method.

Similar to the kneading method

Suitable for construction on steep slopes.

Compared to mortar blowing, it has adhesive strength, so dripping when sprayed is extremely reduced. As a result, the amount of loss is smaller than that of mortar. (About 40% loss)

The strength is equivalent to that of normal mortar blowing.

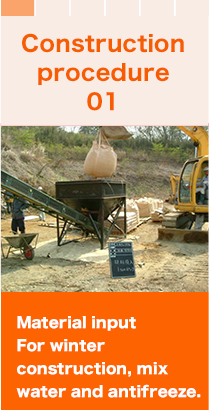

There are 25 kg bags and 1 ton bags for transparent lump soil, which are carried in according to the construction conditions.

25kgenter

1t bag enter

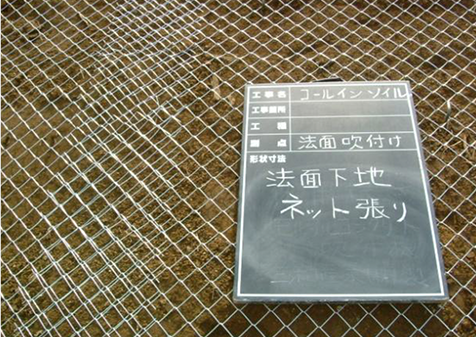

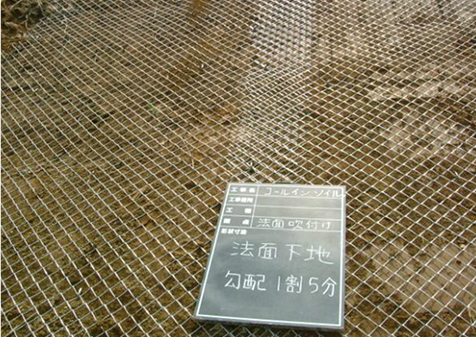

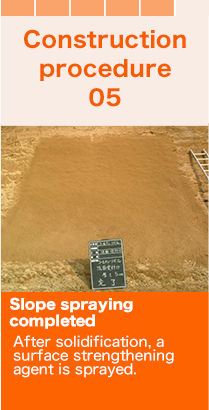

For the base of slope spraying, weeds and roots appearing on the surface are removed while the slope is straightened, and the lath tension on the slope is fixed with anchor pins, and a separator that matches the spray thickness is used. Install and use as a base.

There are diamond-shaped wire mesh, nylon net, etc. for the lath tension on the slope, and these are firmly fixed with anchor pins.

Rhombus wire mesh 2Ф×50mm

Rhombus wire mesh

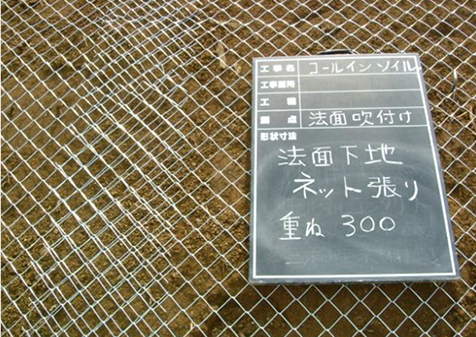

It is desirable that the overlapping width of the diamond-shaped wire mesh and nylon net is 300 mm or more. As for the anchor pin, 16Ф, L = 400mm is lathed at 8 pieces / ㎡ or more, and auxiliary anchor 9Ф, L = 200mm is arranged at 1 piece / ㎡, and the diamond-shaped wire mesh is firmly fixed to the slope. In addition, one separator (for 50 mm) / ㎡ is arranged according to the spray thickness to secure the first thickness.

Rhombus wire mesh stacking width 300mm

spacer 50mm用

Regardless of the slope, the lath tension method is used.

Depending on the height, it may be necessary to secure a foothold.

Slope gradient 1.0% gradient

Slope gradient 1.5% gradient

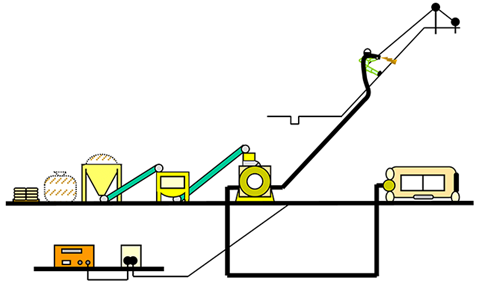

The slope spraying machine uses a mortar concrete spraying machine.

Sanwa industry Manufacturing

| Model SLS-11 | Remarks | |

|---|---|---|

| Construction capacity | 3~6m3/h | |

| Maximum particle size of aggregate | 20mm | |

| Optimal particle size of aggregate | 15mm Less than | |

| 1Batch input capacity | 0.12~0.15m3 | |

| Working air pressure | 9kg/cm2 | |

| Material hose diameter | 38~50mm | |

| Horizontal maximum transport distance | 200m |

Slope gradient 1.0% gradient

Slope gradient 1.5% gradient

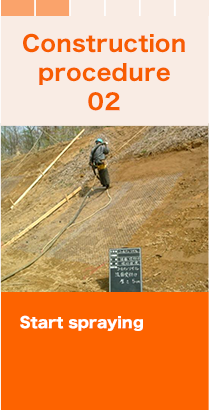

By the flow test, the soil and water mixing ratio are selected and sprayed with a sprayer.

Before the slope construction, perform a trial spray using veneer plywood, check the viscosity that makes it easy to spray, and then perform the spray.

In the case of a large area, the workability is improved because the work is done mechanically rather than the kneading method.

Trees planted on the slope do not die, and you can take measures to prevent weeds around them.

Since the raw material is a natural material, it is environmentally friendly and can be crushed and returned to the soil when not needed.

It has excellent water retention and water permeability, and also has the effect of reducing reflection in midsummer.

It takes about 5 minutes to touch, and about 10 minutes to be strong enough for a person to walk.

The final strength is equivalent to that of normal mortar blowing.

The image is similar to the clay wall used in the past.

Compared to mortar blowing, it has adhesive strength, so dripping when sprayed is extremely reduced. Due to this,

The amount of loss is smaller than that of mortar. (About 20% loss)

* Install a lath net, mix toukon soil + water and spray.

Thinking about our future and the global environment ...

Thinking about our future and the global environment ...